We love challenges

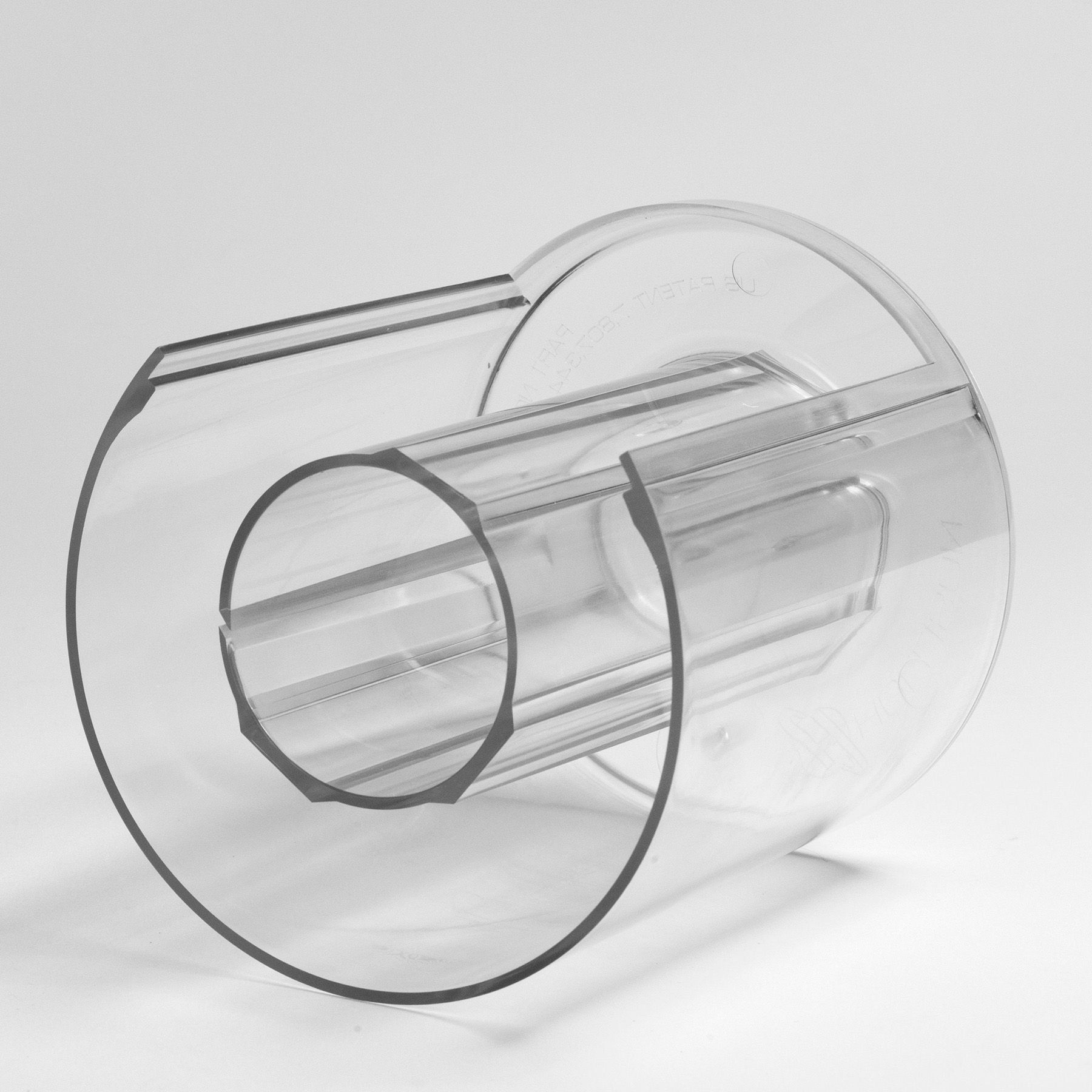

As a plastic container manufacturer, Specialty Container manufactures and maintains in stock a variety of wide mouth plastic containers, plastic lids, plastic pre-moistened wipe towel dispensing lids, wall mounted container holders, and paste soap wall mounted dispensers for a wide variety of markets including:

- Towel wipes

- Automotive

- Paste Hand Cleaner

- Paste wax Automotive/Marine/Aircraft

- Industrial/Commercial ink

- Personal care

- Sanitation

- Janitorial

- Automotive/Industrial grease

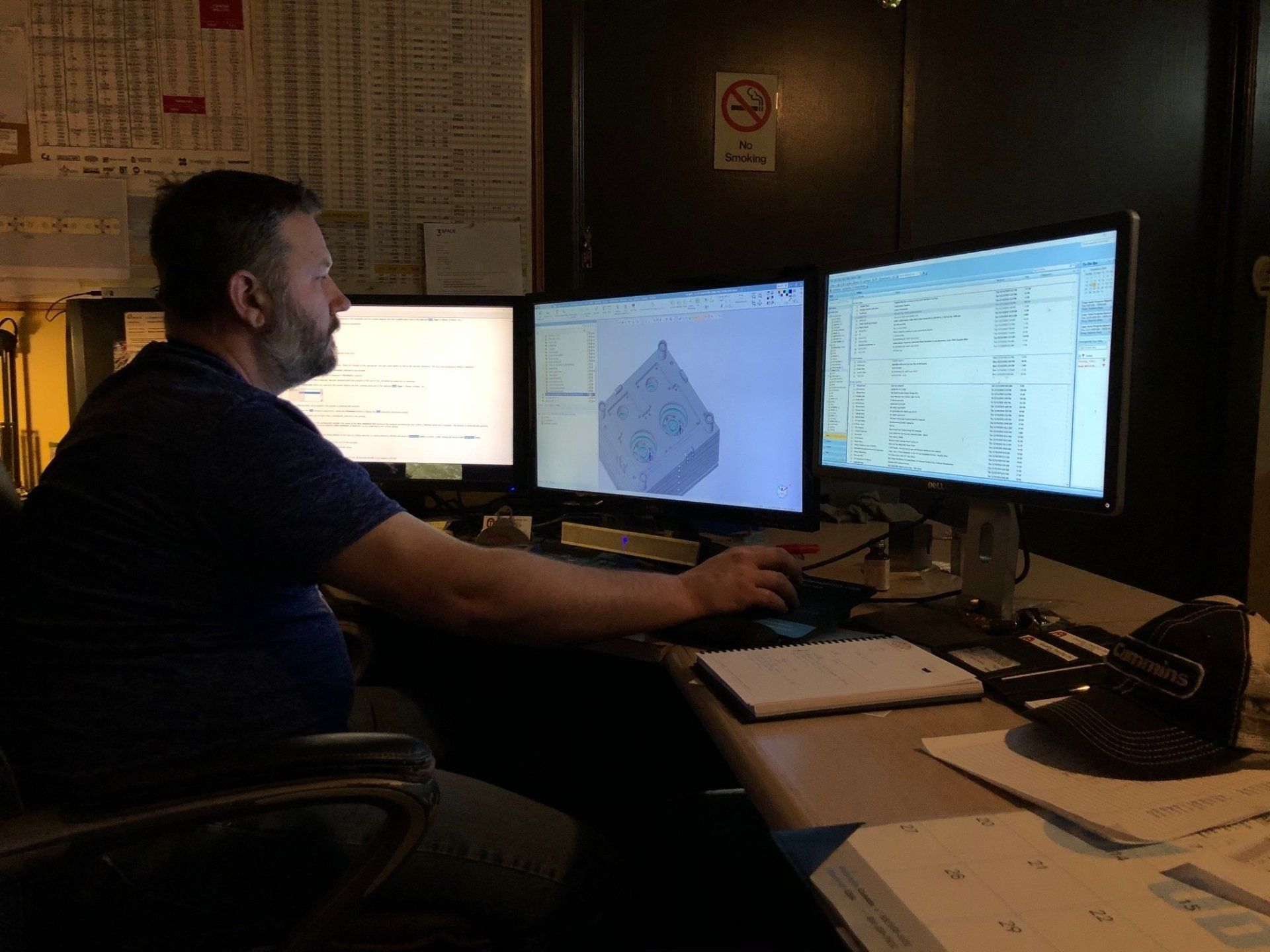

- Design, develop, prototype, to production of custom parts and molds for a wide variety of innovative products

About Us

Specialty Container Inc, a plastic can & canister manufacturer, in business since 1980, is dedicated to the following philosophy:

- To work with our customers to develop and manufacture quality plastic cans, canisters, plastic lids and towel dispensing closures, as well as a variety of innovative ideas in other fields, that fill the ever changing needs of their market.

- From concept, prototype, and manufacturing, continually working to develop interesting new innovative ideas and designs for improving plastic cans, canisters, and lids that give our customers an edge in the market and keep them ahead of the pack.

- Work with our customers in filling specific needs of their market, sometimes sharing in the cost of development and prototypes for test markets.

- Manufacture plastic cans, canisters, and plastic lids of the highest quality possible.

- Provide predictable on schedule rapid response from order to shipment.

- To be the first and the best at competitive costs.

BRIEF HISTORY

From the late 1940’s the paste type hand cleaner industry was using metal lithographed cans and lids for their 4 ½ lb and 1 pound can sizes. Metal cans were plagued by rust problems in the seams and lid fit. Labeling the cans was a costly multistep operation requiring large minimums with long lead times.

In 1980 Specialty Container was formed as a plastic container manufacture to produce and decorate plastic cans and plastic lids as a solution to the rust and labeling problems.

In 1986 developed quart and gallon plastic cans and canisters for the national mastic floor tile industry.

In 1987 designed and developed a dispenser for paste type hand cleaners and added numerous other plastic can sizes.

In 1988 continued to expand by adding more presses to our off-set lithography capabilities.

By 1989 branched into other markets in a major diversification of products including grease, cosmetic, janitorial, powdered cleaners, and additional paste soap plastic containers.

In 1990 entered the commercial ink plastic can market with the addition of 1 lb. and 5 lb. plastic ink cans.

In 1993 additional ink cans were developed with the addition of “impact resistant cans”. Plastic ink cans that can be dropped or handled more roughly without rupturing.

During the late 1990’s entered the “wipe” towel dispensing market with the introduction of various pre-moistened towel wipe canisters and towel dispensing lids.

In 2000 started purchasing plastic feed stock in rail cars to lower cost.

In 2005 moved into the automotive / marine / aircraft /paste wax markets with improved closure designs and customized containers.

2008 continues to expand with the addition of more production capabilities and the addition of the latest high tech dry offset lithography printing presses.

2009 developed commercial ink containers to meet the requirements for both “standard” and “UV” ink formulas.

2009 began utilizing the 3-D CO2 laser abrasion below surface printing plates known as (Stealth Screening) Carey Color Inc. (careyweb.com)

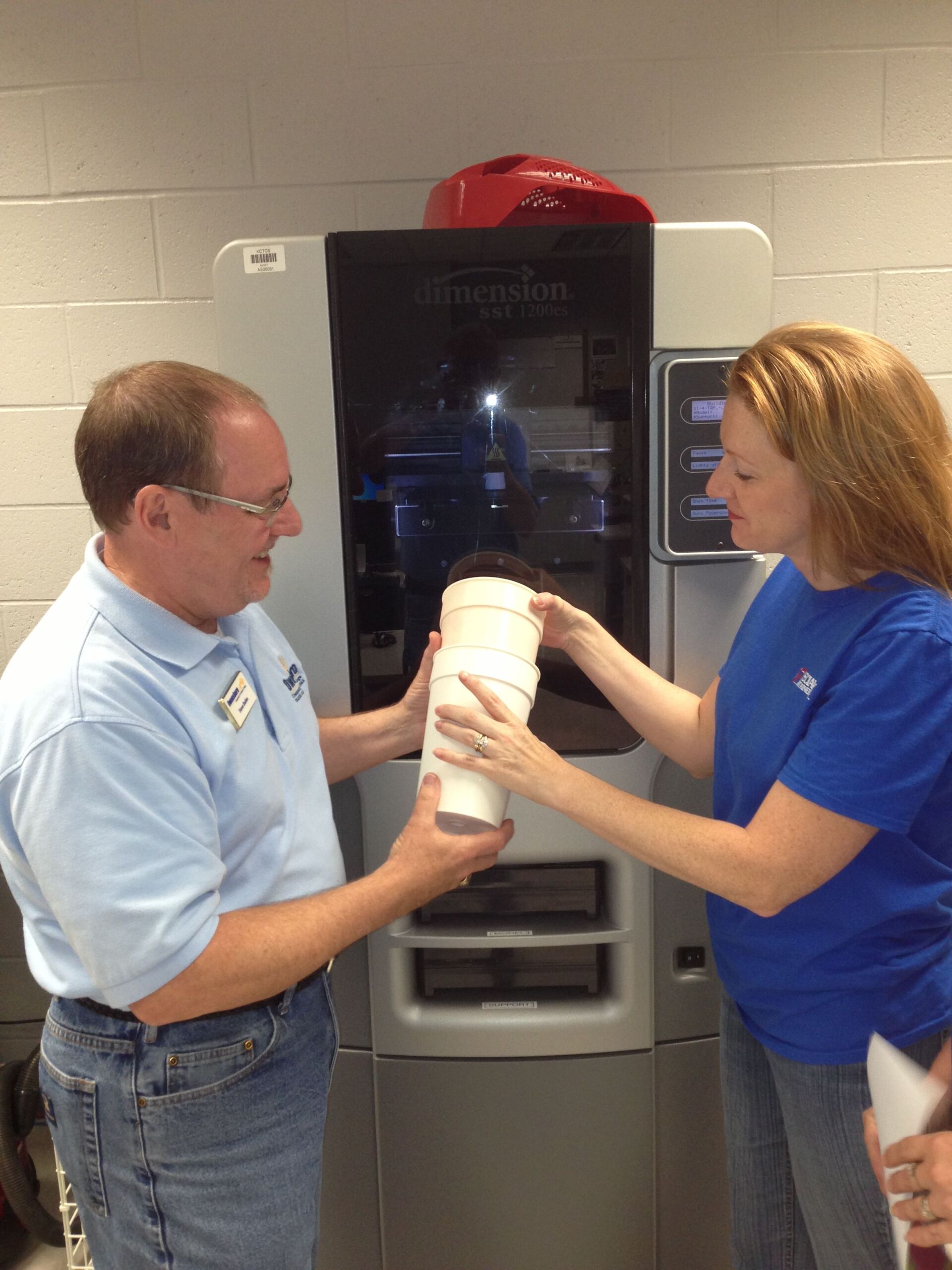

2010 first use of 3D Printing in part and mold design

2011 added additional dry offset full color process printing presses

2012 developed dispensing closures with handles to further expand our towel container line.

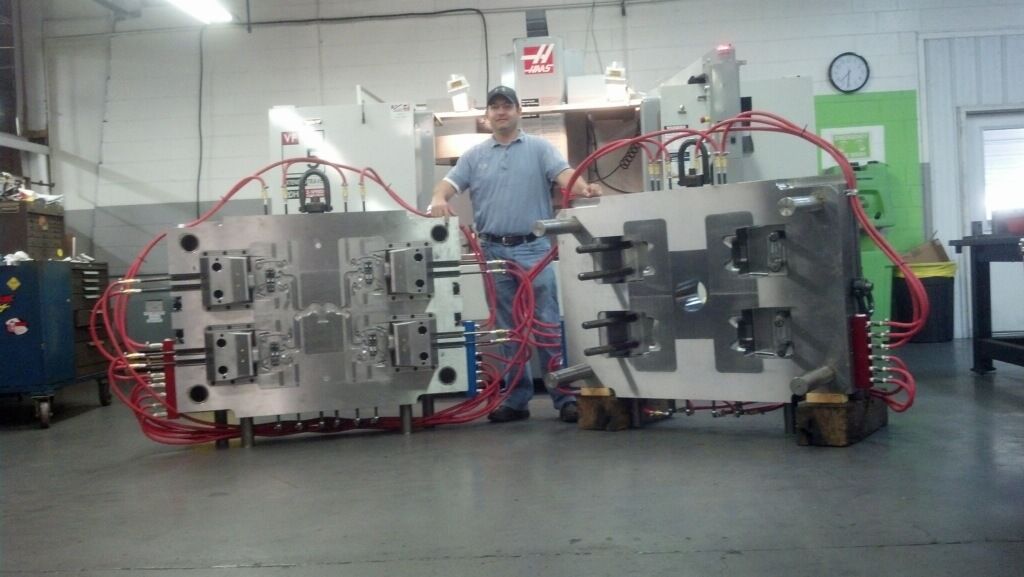

2014 developed the tooling for Hollison (www.hollison.com) Housing and chamber (A major advancement in the food safety industry by near continuous testing developed by Hollison in food processing).

2014 First use of 3D Printing for limited production parts

2014 A second molding facility added to operations

2015 first use of robots for in-mold labeling