Welcome to Specialty Container

Specialty Container is a full service plastic container manufacture that provides our customers with quality molded plastic cans, canisters, and closures for a variety of applications that include:

- Pre-moistened wet wipe towel cans, and buckets.

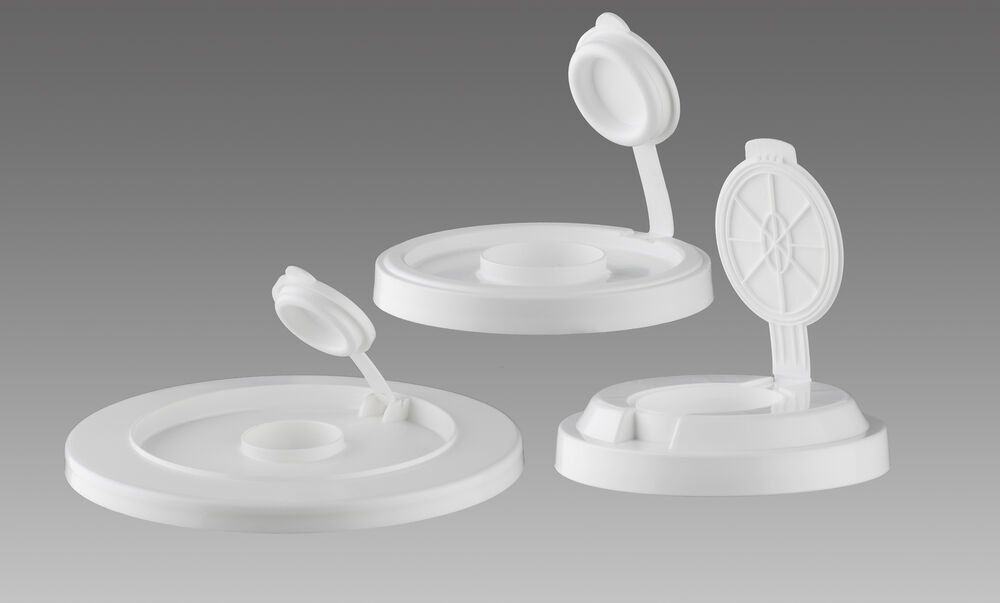

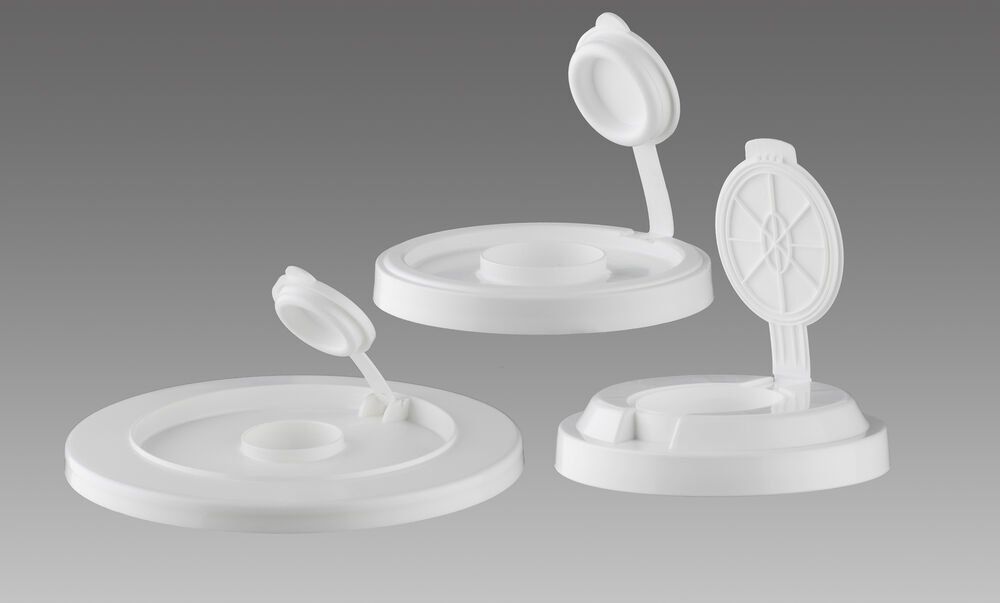

- Towel dispensing lids and closures.

- Straight sided and tapered cans and buckets.

- Traditional lids and closures for straight sided and tapered cans.

- Plastic commercial and industrial ink cans and lids. (Suitable for UV and traditional inks.)

- Paste wax cans.

- Crème or paste type hand cleaner cans and closures.

- Automotive and industrial grease cans and closures.

High quality dry offset lithography (full color process) is available for labeling most containers.

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

-

Straight Sided Cans & Closures

ButtonWrite a short description.

-

Tapered Cans, Buckets & Closures

Button -

Towel Containers & Dispensing Closures

ButtonWrite a short description.

-

Commercial/Industrial Ink Cans

ButtonWrite a short description.

-

Plastic Lids & Closures

ButtonWrite a short description.

-

Dispensers & Wall Mounting Brackets

Button

Let Specialty Container Work for You

Specialty Container can also provide a custom plastic can from design through mold development, label design, prototyping, production and labeling. Our rigid quality control standards

and short lead times mean orders will arrive on time and meet expectations.

Low cost, high quality, short lead times and vertical integration. Everything you need in one place.